“The BlueConduit Model has allowed us to reduce the overall number of hydrovacs we need to do to confirm service material. This means we can focus hydrovacs on the services of greatest uncertainty and spend more resources on removing lead servicing lines, ultimately improving public health.”

Wendy Krkosek, Ph.D., P. Eng., Water Quality Manager, Halifax Water

Community Overview

Halifax Water serves roughly 360,000 customers throughout the Halifax Municipality in Nova Scotia, Canada.

Halifax is an immediately recognizable North American city. It’s appeared on maps for more than 250 years, and is an important naval outpost situated on one of the world’s largest, deepest natural harbors. That history notwithstanding, the 670,000-person community we currently think of as ‘Halifax’ is fewer than 30 years old. Present-day Halifax was created by the provincial government in 1996, when it gathered all of the municipalities within the boundaries of Halifax County (including the cities of Halifax and Dartmouth) into a single regional unit: the “Halifax Regional Municipality” (HRM). The HRM is home to more than half the population of the province of Nova Scotia, and continues to be a key Canadian commercial, financial, and industrial center.

Although Canada currently has no statutory requirement mandating a set timeline for lead service line replacement (LSLR), Halifax has prioritized replacing lead service lines as quickly and completely as possible. This has resulted in an advanced LSLR program that, in most aspects, is now considered “best practice”—despite facing some significant practical challenges.

Halifax Water’s “Get the Lead Out” Program at a Glance

- Will replace all lead service lines by 2038 at no cost to the property owner

- Avoids delays and equity issues by taking financial responsibility for replacement of both the public and private side of the lateral

- Coordinates with street paving and renewal schedule (minimizing disruption and cost)

- Prioritizes individual replacements for customers most at risk from lead exposure

- Anxious property owners can opt to replace their lateral immediately by hiring a qualified contractor at their own expense; Halifax Water will reimburse up to 25 percent of the total cost (maximum $2,500CAD)

- More information about their get the lead out program at the Halifax Water website

Challenges

A lead service line replacement program is only as good as the lead service line inventory (LSLI). Given its unique municipal history, Halifax Water’s initial LSLI had many weaknesses. For example, the merging of communities during amalgamation included merging records. Differences in historical record keeping practices in different communities mean there was significantly less data available for the Dartmouth water system.

Given the amount of uncertainty in their records, building a reliable inventory was proving to be time and resource intensive. Validating the line material for each unknown lateral was a cumbersome multi-step, multi-department process that included:

- Reviewing paper and digital records

- Checking for any photos taken during recent meter replacements

- Contacting the property or homeowner for any information they might have about their plumbing

- Visual inspection via hydroexcavation

This was further complicated by the limited number of hydroexcavation trucks at their disposal, which were shared with other projects (like routine maintenance and repair). As a consequence, each visual inspection cost at least $500CAD and had to be triaged among repair and maintenance projects, creating further delays.

Halifax Water needed to increase confidence in its inventory while reducing the timeline and resource burden it took to create that inventory.

Solution & Results

Halifax approached BlueConduit in late 2019 for assistance in improving its LSLI. BlueConduit is a water analytics company based in Ann Arbor, MI, known for its trailblazing predictive machine-learning approach to determining service line material, locating lead service lines, and helping communities and utilities prioritize action based on risk of lead exposure.

BlueConduit began by bringing together all of the data Halifax Water had for both public and private service lines throughout its current service area (including Dartmouth). These data were used to create a model that included the entire system. That model used data about parcels with known and validated service line material to extrapolate the probability of lead content in any given unknown service line.

But the inherent problem of relying on available data is that you have no way of knowing to what degree this is truly representative of the entire system. To address this, BlueConduit used that initial model to generate an inspection list of several hundred properties drawn from parcels with the highest uncertainty. Halifax Water would then perform hydrovac visual inspections at these parcels, and send its findings to BlueConduit for integration into the model. The result was a more representative model, which is a much more accurate model.

At this stage, the updated model was used to create a new set of service line material predictions. BlueConduit found that the likelihood of lead changed by more than 10 percentage points at thousands of homes. Although average change was low, there was substantial change on many parcels. For some homes there was a 60 percentage-point change in the likelihood of lead being present in the service line.

Data Fed to the Initial Halifax Water System Model

- Verified service line material (when available)

- Service line historical record (if any)

- Parcel ID, address, longitude/latitude, and acreage

- Construction records, build year, and property class/zoning

- Recent surveys

- Home/property value

- Water test results

- Service line diameter/length

- Water main size and material

- Water bill information

- Census information

- Fire hydrant information (distance from property, hydrant company, etc.)

How Do We Know It Works?

Whenever we intervene, it’s important to check our assumptions and biases: Is what we’re doing actually better than a simpler alternative approach? Is the predictive model able to locate all of the lead in the system?

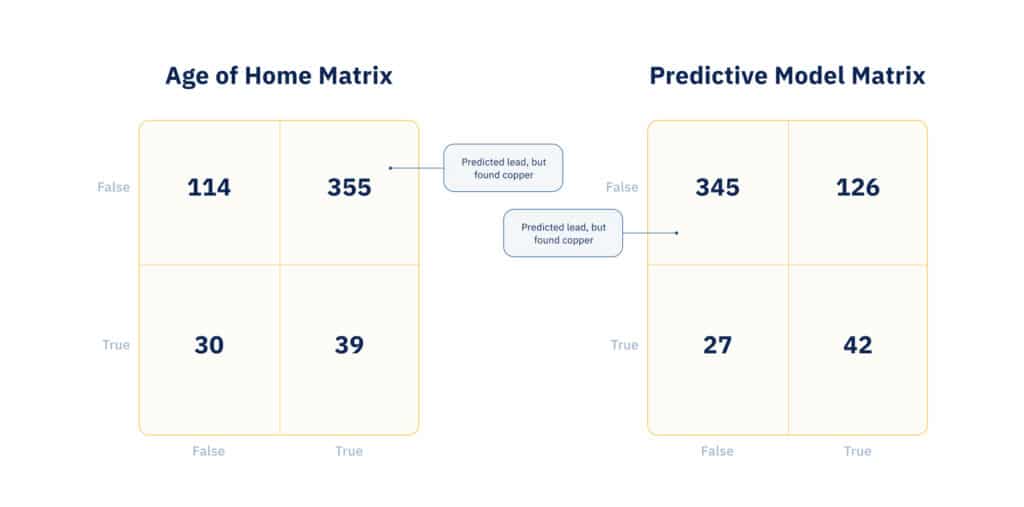

For example, in many cities, the age of the home—which is usually easily established with great confidence—is an excellent predictor of whether the building will have lead service lines. This is the case in Detroit, MI, a city that is similar to Halifax in many regards. Could HRM officials have simply relied on the age of structures, and saved themselves a great deal of work and expense?

No!

The evaluation matrices in Figures 1-3 are based on validated data collected in Halifax. The left half of Figure 2 shows the results when you look for lead service lines in HRM solely based on build year. On the right are the results of BlueConduit’s predictive model. As you can see, relying solely on the age of the structure results in an enormous number of false positives—in fact, it mostly yields false positives. In Halifax, it turns out that build year is a significantly worse predictor than a simple coin toss. If you stood in front of two Halifax homes and chose to dig at one home based on a coin flip, you would find lead more often than if you relied on just the age of the structure to predict the home’s service line material!

Meanwhile, a predictive model would more often correctly predict the service line material, with far fewer false positives (i.e., instances where you dig up a yard ready to replace a lead line, only to discover copper).

Is the predictive model able to locate all of the lead in the system?

How good is the model at finding lead where we think there is lead?

Results

Because BlueConduit’s predictive model proved so much better than other heuristics, it relieved the need for hydrovac inspections before every replacement, which both lowered costs and accelerated Halifax Water’s LSLR program overall.

More importantly, this approach to LSLI continues to improve over time. At the end of every working season, Halifax Water sends additional validated data to BlueConduit, which are then integrated into the model. BlueConduit updates its predictions accordingly. These new and more accurate predictions are then sent back to Halifax so that officials can plan their next season of work, ensuring that their efforts create the greatest benefits as quickly as possible.

“It’s about getting a clearer picture of the unknown,” explains Ian Robinson, President and Chief Operating Officer at BlueConduit. “The active machine-learning model is a way to quickly get a clearer picture, and to continue to learn over time as more data come in from the work that’s done in the field. The model continues to improve, generating useful information that can help guide decision making, improve communication, and ultimately create efficiencies.”

Parting Words

“The quicker that you can mobilize crews to get the lead out of the ground, the less time your people spend living with lead. That’s our ultimate goal at BlueConduit. That’s the end benefit that we want our customers and their communities to enjoy: fewer days with lead pipes going from the water main to the house.”

Ian Robinson, President and Chief Operating Officer, BlueConduit