In Fall 2015, test results showed elevated levels of lead in Flint’s drinking water and Dr. Mona Hanna-Attisha’s testing of blood lead levels in children across the city also revealed elevated lead levels, which confirmed that lead from the water system was impacting the health of Flint’s citizens. Mayor Karen Weaver declared a State of Emergency in December 2015. The Environmental Protection Agency (EPA) Emergency Order to the City of Flint on January 21, 2016, required the city to immediately re-start their corrosion control program. The corrosion control program mandated a combination of orthophosphates and chlorine be introduced into the drinking water system. Lead had been leaching from the city’s pipes for over two years as a result of improper water treatment after the Flint River became the city’s primary water source in April 2014.

During the first week of February 2016, Mayor Weaver appointed me to plan a solution for this crisis. The City of Flint and the State of Michigan had just received a follow-up letter from the EPA requiring immediate action on corrosion control. But corrosion control was a temporary fix, a mere replacement of the lining of lead service lines (LSLs) to ensure that drinking water would not come into contact with the lead pipes. This response presumed the long-term continued use of LSLs – the very source of the drinking water contamination – and did not take into account the time needed for the corrosion controls to work through the water distribution system and become sufficiently present in all service lines.

The urgency of Flint’s public health crisis and the unknown scope of the problem demanded a more complete solution: the removal and replacement of the LSLs themselves. Therefore, on February 9, 2016, the City of Flint announced the FAST Start Program to replace the city’s LSLs, and the EPA Flint Safe Drinking Water Task Force (EPA Task Force) supported our approach.

Thirty Lines in Thirty Days

In March 2016, the Lansing Board of Water & Light (BWL) method of extracting LSLs and replacing them with copper pipes was publicly demonstrated at the home of a pregnant mother and small child – two of the most at-risk populations. After that initial demonstration, we targeted an additional 30 homes from across the city for our LSL replacement pilot project. These homes had LSLs according to city records and high lead levels reported through sample testing.

As we launched this “30 Lines in 30 days” pilot, we discovered that the city’s records of service line material composition were not reliable and could result in unnecessary excavations. We discovered that over time many service lines had been replaced without proper documentation. Consequently, many homes had incomplete or nonexistent service line records. For example, lead could be present from the water main to the curb box and then the remainder of the service line could contain a variety of materials such as lead, copper, galvanized steel, or plastic. Upon excavation, we found that one of the homes in the pilot project had complete copper service lines, which meant the inaccurate city records had led to unneeded work.

Expanding Beyond the Pilot

As our FAST Start Team moved forward with expanding our LSL replacement efforts beyond the initial pilot project, we recognized that we needed to establish clear definitions, processes, and protocols to guide our replacement efforts if we hoped to be successful at scale and align ourselves with the recommendations of the EPA Task Force. We planned for full service line replacements and would not allow for any partial replacements.

This commitment meant that we would replace any LSLs that were found, whether those pipes were found on the city-owned portion of the line (i.e., from the water main to the curb box) or the resident-owned portion of the line (i.e., from the curb box into the home). We also consulted with Dr. Marc Edwards, professor of civil and environmental engineering at Virginia Tech and one of the world’s leading experts on water corrosion in home plumbing, to determine that galvanized pipes and any materials attached to LSLs would need to be replaced to remove the risk of future lead exposure.

Data Challenges Threaten

However, less than 60 days into the FAST Start Program, our team faced a number of data challenges that threatened to raise project costs and decrease the likelihood that all lead would be removed from Flint’s water system.

- The city’s system of record for service line installations and replacements was antiquated and the information recorded was often incomplete and incorrect. When a plumber sought a permit for service line installation or replacement, the site address and summary of the work completed was recorded by hand, in pencil, on a 3×5 inch index card. These index cards were not organized in any fashion (such as by year or address) and the only other records available were copies of the original neighborhood plat maps, which were often worn by use and therefore illegible.

- Using these records, the city could only confirm that 5,000 of the projected 15,000 service lines within the water system were made of lead.

- The service line composition records often only included information related to the city-owned portion of the line. Thus, the quantity and location of mixed galvanized and LSLs was unknown.

- The highest concentrations of homes with LSLs could not be determined by street, neighborhood, or ward, because there were too many unknown pieces of information related to whether a LSL had been replaced or ever installed.

- We were committed to prioritizing the replacement of LSLs at the homes in which the most at-risk citizens resided, which we defined as children under 5 years of age, pregnant women, those with compromised immune systems, and the elderly. However, we did not have the demographic data necessary to determine which homes met that resident criteria.

A Potential Solution: Data Science

We had considered a number of methods for how to determine the quantity and location of LSLs and then our team was approached by Eric Schwartz, professor of marketing at the Ross School of Business at the University of Michigan (U-M), and Jake Abernethy, professor of computer science at Georgia Tech. They presented a potential solution to our data problem that leveraged their expertise related to statistical analysis and machine learning. They had received funding from Google to create a mobile app that would allow Flint residents to determine their homes’ lead risk level.

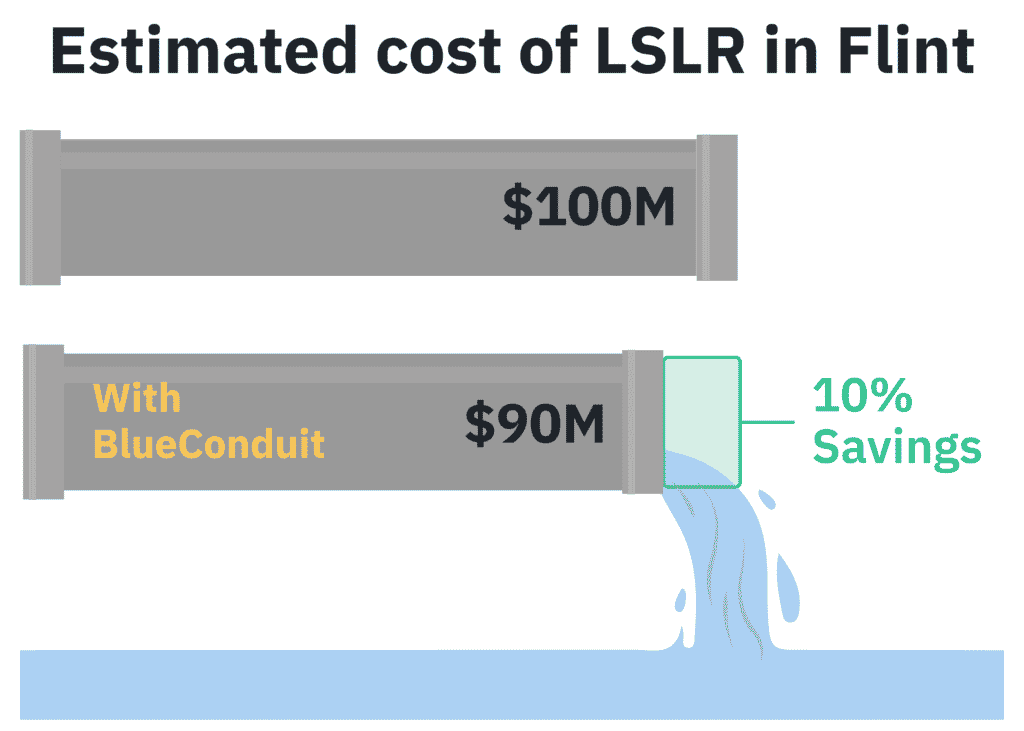

Their early work on the project, with contributions from Alex Chojnacki and Arya Farahi (U-M students) and Jared Webb (Brigham Young University student), estimated that their method of inspecting, identifying, and targeting pipes for replacement could save the City of Flint as much as $10 million – a 10% savings that was roughly equivalent to the cost of replacing LSLs for an additional 2,000 homes. The City would realize much of the savings by avoiding unnecessary pipe inspections and excavations. Each each unneeded dig would cost the city thousands of dollars.

Our FAST Start Team initially provided Eric and Jake’s research team with a dataset of 50,000 city parcels. The team then added additional data gleaned from hand-drawn maps from the city’s water department. Together, these data sources provided the base to predict the probability of the presence of lead or other unsafe pipe materials on a home-by-home basis.

Strategic Replacements at Highest Risk Homes

The predictions generated by the research team allowed our FAST Start Team to strategically deploy replacement crews to the homes with the highest probability of the presence of lead. This targeted approach was particularly critical in the early stages of our replacement program when we had limited funding.

In my next post, I’ll discuss how we worked to improve the accuracy of service line materials records going forward and continued to leverage machine learning to make sure our LSL replacement efforts were as efficient, cost-effective, and equitable as possible.