When water mains break, it can be a disruptive, expensive, public headache for water systems. Many factors contribute to a water main leaking or breaking, including the soil surrounding the water mains, which plays a critical role in its longevity.

Did you know? Corrosive soils can dramatically shorten the lifespan of water mains, leading to costly repairs, service disruptions, and potential safety hazards.

Corrosive soils can include soils with an extreme pH value (less than 4 or greater than 8), high sulfate content, chloride ions, redox potential, low soil resistivity, and even those with high moisture content.

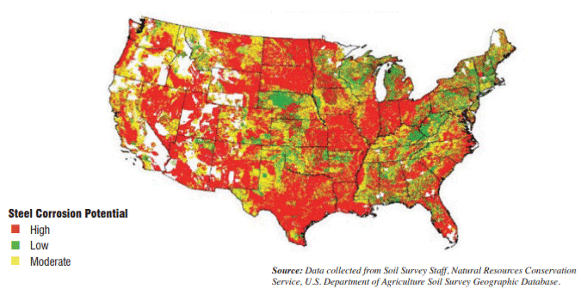

Corrosive soils impact nearly every water system in the US. In the recent Utah State University study, 75% of utilities surveyed reported operating pipes in one or more soil areas with moderate or highly corrosive conditions.

Image courtesy of USU.

Understanding the mechanisms by which corrosion occurs is the first step towards implementing effective mitigation strategies.

How soil corrosivity impacts water mains

The deterioration of metallic pipes, primarily cast iron (CI) and ductile iron (DI), due to corrosive soils is a widespread issue. The severity of soil corrosivity is determined by factors such as:

- Moisture Content: Damp soil facilitates the flow of electric currents, accelerating the corrosion process.

- Chemical Composition: The presence of acids, alkalis, sulfates, and chlorides in the soil can react with pipe materials, compromising their integrity.

- Electrical Resistivity: Low resistivity soils enable greater electrical current flow, increasing the rate of corrosion.

- Microbial Activity: Certain bacteria thrive in anaerobic conditions and produce corrosive byproducts that attack pipes.

The danger lies in the silent and invisible nature of these corrosive processes. By the time a water main break occurs, significant damage has already taken place.

What happens to impacted mains

Corrosion in water mains is primarily an electrochemical process, with corrosive soils acting as the electrolyte. When different metals are present, for example, at pipe joints or due to variations in soil composition, an electrical circuit is created. This leads to the flow of electrons from one metal to another, causing the deterioration of the more reactive metal.

This process manifests as:

- Corrosion Pits: Localized areas of metal loss that weaken the pipe structure.

- Graphitization: A form of corrosion specific to grey cast iron, leaving behind a brittle network of graphite flakes.

Over time, these weaknesses make the pipe vulnerable to various stresses, ultimately resulting in:

- Circumferential Cracks: The most prevalent failure mode, accounting for almost half of all water main breaks.

- Longitudinal Cracks: Less common, but potentially more damaging, these cracks run along the length of the pipe.

Moving beyond reactive measures: The power of predictive modeling

Addressing corrosion issues proactively can extend the lifespan of pipes by decades, delaying costly replacements. Predictive modeling offers a proactive and strategic approach to water main asset assessment and management.

By leveraging multiple internal and external datasets including, but not limited to, soil type, BlueConduit’s Water Main Predictions solution can forecast future failures, prioritize assessment and maintenance, optimize replacement cycles, and more. And it is delivered right into Esri, keeping your work and data all in one simple source-of-truth.

Embracing predictive modeling is an investment in the long-term sustainability and resilience of water infrastructure. By leveraging the power of data and foresight, water utilities can ensure reliable service and responsible stewardship of this vital resource for generations to come.

Ready to learn more? Reach out to schedule a consultation today.