Michigan CDSMI

Michigan’s Department of Environment, Great Lakes, and Energy, Drinking Water, and Environmental Health Division (EGLE) released its Complete Distribution System Materials Inventory (CDSMI) Overview and Minimum Service Line Material Verification Requirements.

As part of its guidance, EGLE says “Water supplies are not expected to physically verify every service line, but rather a statistically sound subset. To effectively evaluate the accuracy of service line records and/or predict service line materials, a representative, uniformly random number of service lines must be physically verified.”

EGLE describes two exceptions to this verification guidance:

- A water supply may avoid the material verification process if all potable water service lines within the water supply meet the definition of “known”.

- Water supplies may exclude service lines four inches or more in diameter.

Guidance Summary

- The CDSMI is due to EGLE by October 16, 2024. EGLE suggests water systems complete material verification by the end of 2022 to allow for any additional activities that may be necessary to complete the inventory.

- To evaluate the accuracy of potable water service line records and/or predict service line materials, a statistically sound, uniformly random number of “unknown” service lines must be physically verified.

- Written notification must be provided to the owner and occupant(s) of any building with a service line known, or assumed, to contain lead in any portion.

Material Verification Process

- Identify all potable water service lines of “unknown” material.

- Identify how many service lines should be physically verified.

- Randomly select service lines for physical verification.

- Create a tool for tracking records and materials during verification.

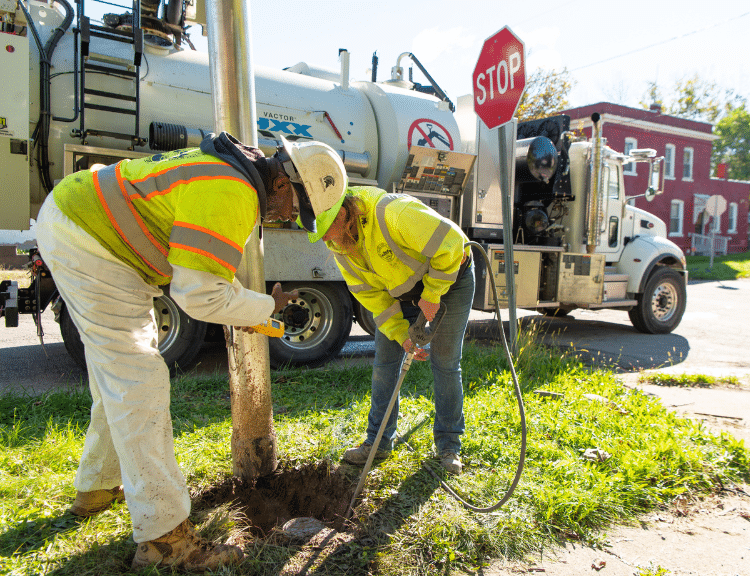

- Conduct three- or four-point physical verification.

- Record results of physical verification in tracking tool.

- Evaluate results of the physical verification to assess reliability of existing records and determine next steps.

EGLE’s guidance was created in collaboration with the University of Michigan and with consideration of the ASDWA/BlueConduit white paper “Principles of Data Science for Lead Service Line Inventories and Replacement Programs.”

Detailed information about Michigan’s Lead and Copper Rule can be found on EGLE’s website.