You’ve been hard at work on your lead service line inventory and your team is nearing inventory completion — congratulations, that’s a huge accomplishment! This inventory is a critical first step to getting the lead out for your community.

But even with a draft inventory complete, your compliance work isn’t done. Did you know that the primary value of predictive modeling comes after the initial inventory is created? Here’s why:

1) You still have unknowns in your inventory

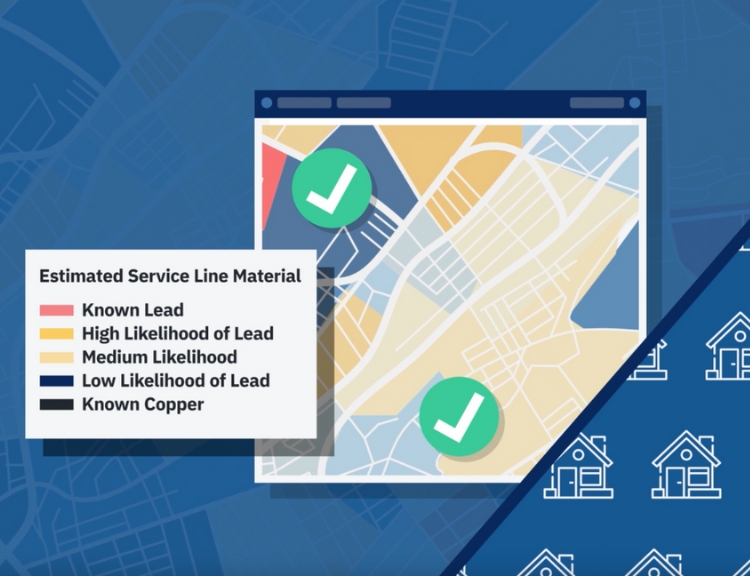

Without clarity on the likelihood of lead for your unknowns, you don’t know the true scope of lead in your system, which makes it difficult to acquire funding or do meaningful planning around replacements and other next steps.

2) You need a clear plan for next steps, including replacement, that’s efficient, effective, and defensible to your community

This isn’t a future problem, it’s a today problem; under the upcoming Lead and Copper Rule Improvement (LCRI), you will be required to create a publicly available replacement plan that includes, among other things, your approach to unknown management and a plan for replacement prioritization. If you don’t use predictive modeling or statistical analysis as your approach to unknown management, you’ll be forced to do visual inspections at every service line with unknown materials.

Spoiler alert — this is going to be incredibly time & resource-intensive (take a look at the example below) and slow your ability to make an equitable plan. Additionally, you’ll be required to notify every customer with an unknown line that their SL may be lead, which can be really scary and lose customer trust, especially if you don’t have a clear, defensible plan of action to show them how you intend to follow-up.

3) You want to minimize the burden of replacements (*without losing customer trust)

In the upcoming LCRI (Lead and Copper Rule Improvements), unknowns are treated as ‘assumed lead’ for the purposes of replacement rates and other compliance requirements. So if, for example, you leave 20% of your service lines as “unknown” material, you’re on the hook to replace at a significantly faster rate than if you could show that only a subset of those lines are actually likely to be lead.

What does this look like with real numbers? Let’s assume you have 4,000 SLs of unknown material; under the forthcoming LCRI requirements, you need to replace 10% of your lead service lines per year for 10 years. 4,000 unknowns adds a replacement burden of 400 additional replacements/year — imagine if you could reduce that number to 200, 100, or even 0 using guidance from predictive modeling regarding the likelihood of lead at for each of those lines.

Get Started:

Not sure what steps to take next? BlueConduit can help! Our platform, supported by a team of expert data scientists, can help you:

- Predict lead likelihood for all SLs with unknown materials,

- Provide a clear unknown management approach for your LCRR Replacement Plan,

- Prioritize visual inspections,

- Prioritize highest risk SLs for replacement, and

- Create a strong action plan to get the lead out and stay ahead of compliance requirements.

Let’s get started! Book a demo today.