Proactive Lead Service Line (LSL) Management

Manage unknowns for Service Line Inventory and replacement planning using locally tailored, AI-driven predictive modeling.

Key Features

Precise predictions, streamlined implementation

BlueConduit’s LSL Predictions delivers the most precise, transparent, and user-friendly lead and GRR likelihood predictions for every service line segment. Our solution minimizes the complexity of handling regulatory demands and relationships, making lead service line (LSL) inventory and replacement management remarkably simple and efficient. Whether you’re just getting started or further along in your data analysis journey, BlueConduit is a community partner you can trust.

Our team of expert data scientists generates lead/GRR likelihood predictions using the most rigorous, academically-based AI and machine learning algorithms, supported by a robust process and the best technology tools available to make their work accessible to every water system. For early customers who’ve done the work to inventory and replace lead service lines (LSL), lead service lines were predicted correctly with >90% success.

Physically verifying the material of every unknown service line is expensive, not just in dollars but also in time, opportunity cost, community disruption, and increased compliance requirements. LSL Predictions customers spend 90-95% less on service line material identification and complete service line material identification in 2-3 months, compared to 3-10+ years for physical verification.

BlueConduit’s expert policy team engages directly with state regulators to understand your state’s unique guidance and advocate on your behalf. Our technology ensures your Service Line Inventory data is fully compliant with EPA and state guidance, ahead of the regulatory deadlines.

Our team of expert data scientists generates lead/GRR likelihood predictions using the most rigorous, academically-based AI and machine learning algorithms, supported by a robust process and the best technology tools available to make their work accessible to every water system. For early customers who’ve done the work to inventory and replace lead service lines (LSL), lead service lines were predicted correctly with >90% success.

Physically verifying the material of every unknown service line is expensive, not just in dollars but also in time, opportunity cost, community disruption, and increased compliance requirements. LSL Predictions customers spend 90-95% less on service line material identification and complete service line material identification in 2-3 months, compared to 3-10+ years for physical verification.

BlueConduit’s expert policy team engages directly with state regulators to understand your state’s unique guidance and advocate on your behalf. Our technology ensures your Service Line Inventory data is fully compliant with EPA and state guidance, ahead of the regulatory deadlines.

LSLI Solution

Access BlueConduit’s Platform in Esri, integrated with suite of Esri LSLI applications, including:

- Standardized Inventory Data Management

- BlueConduit Inspection Manager, including recommended inspection list(s)

- BlueConduit Predictions Dashboard

- Updated BlueConduit Platform features and enhancements, as available

Predictive modeling

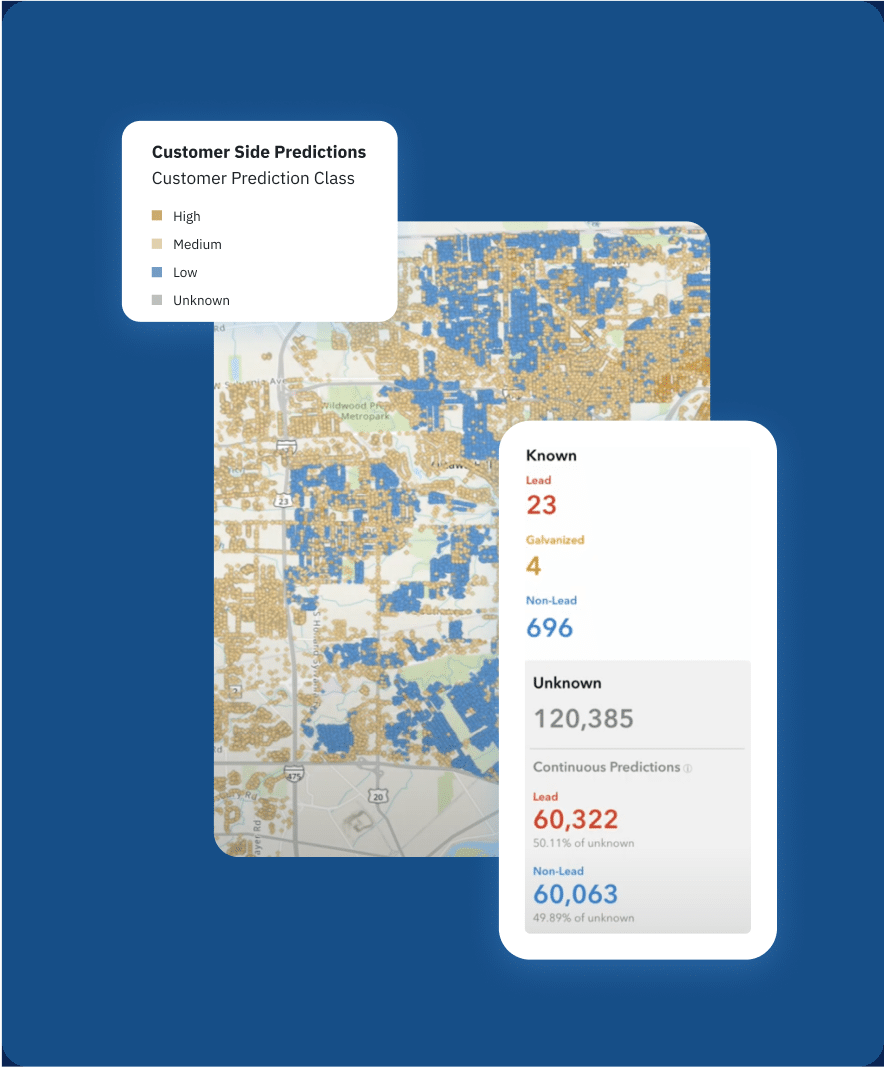

Enhance your existing data with service line material predictions from BlueConduit’s best-in-class machine learning models, including:

- Initial predictions, based on existing inventory data

- Single material modeling (Lead/GRR is treated as a single material)

- Custom, local predictive model development

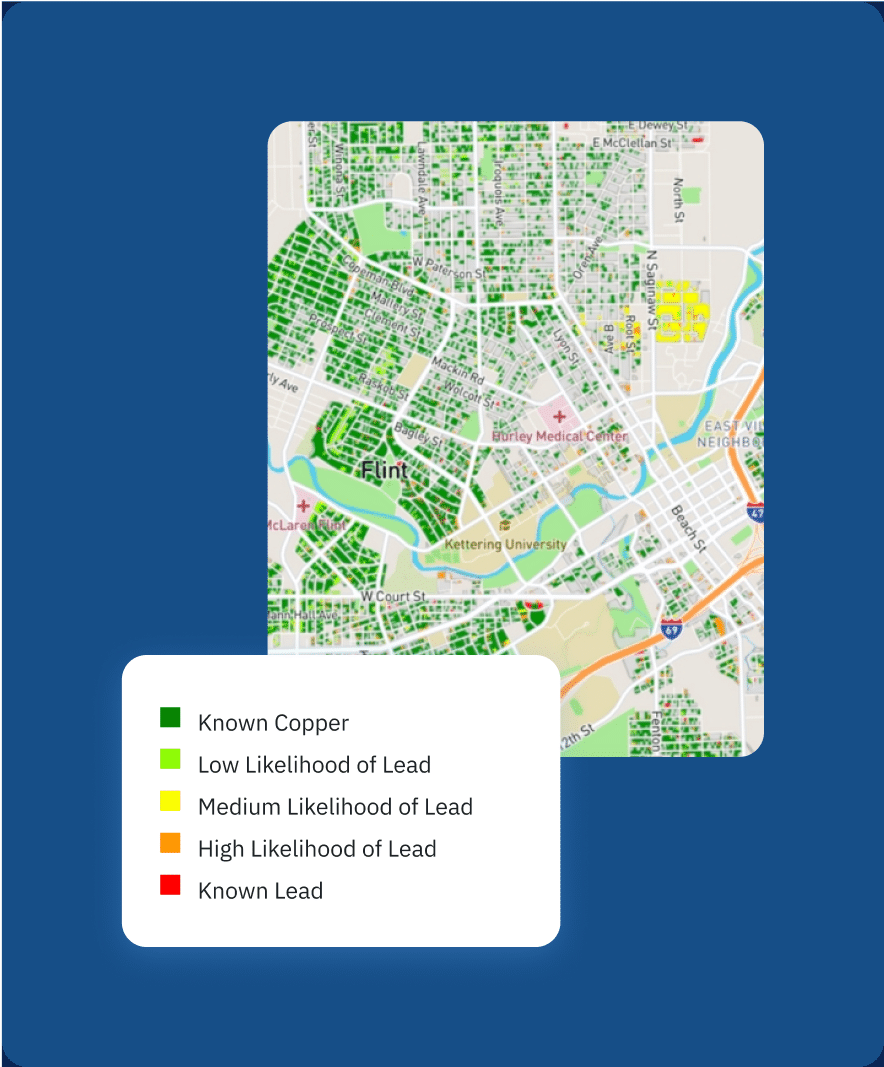

- Lead likelihood predictions for every unknown service line segment (public/private)

- Ongoing material prediction updates

- Prediction explainability [coming 2025]

Classify unknowns

Use predictions to classify service lines with unknown materials as Lead or Non-Lead for your inventory:

- Likelihood of Lead categorization (high/medium/low)

- Classification of unknown SLs based on thresholds and state guidance

- LCRI “Non-Lead” validation manager, including representative samples [coming 2025]

Tracking, Reports, & Communication

Easily, compliantly share inventory data and decisions to multiple stakeholders using:

- Inventory data loaded to state template (annual)

- Embeddable Public-Facing Inventory Map

- Regulator Project plan (as needed)

- Data Analysis Report

- Methodology Report

- Compliance Report (annual)

- Non-Lead Validation Report [coming 2025]

Customer Success

BlueConduit’s team is committed to your success and highly engaged as you use our tools:

- Implementation support

- Policy guidance & support

- Ongoing support conversations

CASE STUDIES

Real-world solutions, tangible results

See how other cities are utilizing LSL Predictions to efficiently and compliantly identify and replace lead pipes.

case studies

case studies

CASE STUDIES

Frequently Asked Questions

Yes, as needed. We can help you standardize and transform your data into a compliant Inventory. For all customers, we also do data reviews for compliance and help you utilize predictions to classify service line materials in your Inventory.

We consider multiple measures of accuracy including recall, precision, confidence interval, and ground truth hit rates, among other model performance metrics. For most customers, depending on the dataset, we are able to deliver our statistical analysis with a 95% confidence level. Learn more about how BlueConduit thinks about accuracy.

Yes, with AI defined as using a computer to do things that a human brain can also do. Specifically, our Data Science team builds machine learning models. We do not currently use artificial neural networks or generative models, such as ChatGPT, for our data science work. Learn more about how we think about and use AI, statistical analysis, and predictive modeling.

It depends on your existing dataset and your state’s guidance. Our models can often generate high confidence predictions with as few as 100-150 representative field verifications. Learn more about our approach to representative sampling.

Yes, based on your state’s specific guidance.

Cost savings are compared to the cost of verifying every service line, assuming an average verification cost of $1,000 per verification, which can include excavation, meter inspections, labor, customer notifications, pitcher/filter kits, etc. Time savings are compared to verifying every service line, assuming the number of verifications for BlueConduit are aligned with MI EGLE’s guidance and statistical best practices.

Unlock your water system's potential:

Partner with BlueConduit for expert lead service line solutions

Discover how our innovative solutions for lead service line management can transform your approach. Let’s partner to ensure clean, safe, affordable water for your community.