Multiple factors are pushing water utilities to be more transparent about pipe materials in their distribution system. These factors include new regulations and increased public awareness about the risk of lead in drinking water. Municipalities and utilities know they have an Environmental Protection Agency compliance deadline (pursuant to current Lead and Copper Rule Revisions) to submit a lead service line (LSL) inventory by October 2024. That deadline might seem far away, but it is coming up quickly. Here are five reasons to build your LSL inventory sooner than later.

1. Residents Are Worried

Residents in your community (and beyond) are rightfully worried that they, their neighbors, or their loved ones may have lead service lines. Current regulatory notification requirements stipulate that letters must be sent annually to households with lead service lines, as well as to households with service lines of unknown material. Many of those “unknown” pipes are likely to be free of lead. Residents receiving that notification letter would needlessly worry about their immediate health and safety. The sooner your community takes action to start sorting out those unknowns, the sooner you will provide anxiety relief and peace of mind for those households who actually have copper service lines. Then you can shift focus to remediation for the properties that have lead lines.

Often communities burdened with lead service lines are ones that have likewise suffered long periods of disinvestment or underinvestment. As such, the communities that need the most help are those with the fewest internal resources to draw upon.

We’re at a historic moment when both the desire to address these long-standing systemic failures and the funding to do so are simultaneously present. Starting your lead service inventory now makes it possible to lock in that support.

2. You Can’t Scope the LSL Replacement Project Until You Start the Inventory

Every community’s drinking water service line inventory is full of not just “unknowns,” but also “unknown unknowns”: water systems are old, humans are fallible, and records are incomplete, illegible, out-of-date, or incorrect. Early visibility on the state of the service line inventory empowers the municipality to take action. The sooner you start this work, the sooner you know what you need to learn.

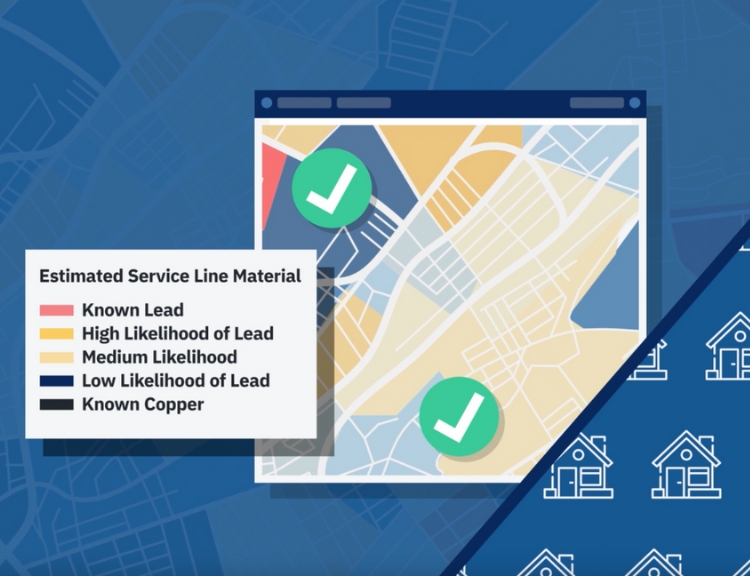

The EPA notes that predictive models have proven to be an effective approach for quickly estimating the probability that a service line is lead, understanding how many lead service lines are in a water system, and expediting lead service line replacement programs by prioritizing areas with the greater concentration of lead service line.

Using machine learning to build a reliable lead service line inventory is an iterative process: you begin with the records you have, test them against the “ground truth” of what you find from field work, and then use those findings to better predict what you’ll find elsewhere in your water system. The inventory gets more accurate over time as more pipe materials are verified, improving the predictions on the remaining unknowns.

The sooner you start this process, the sooner you’ll have the key information you need to start getting the lead out of the ground: how many lead pipes to expect in your system and where they are likely located.

3. Building Your LSL Inventory Is the Keystone

According to the US EPA’s 2021 Lead and Copper Rule Revision, by October 16, 2024, communities must:

- Identify and publicly disclose the locations of lead service lines and service lines of unknown materials

- Have a plan to replace lead and galvanized service lines throughout their water systems and communicate this plan

- Sample water in a selection of locations served by lines made from lead, galvanized, or unknown materials and communicate their findings to residents within 24 hours of getting the results if there is an exceedance

- Notify those who are on lead/galvanized service lines or whose drinking water comes from service lines of an unknown material

A well-developed lead service line inventory is the key to meeting all of these requirements.

Furthermore, utilities prepared with a LSL inventory will be ready if—or when—some governing or regulatory body (be it local governments, state legislatures, or the EPA) require them to replace LSLs at a certain rate. Every state is different. While most are operating on the EPA’s timeline, some locales/primacy agencies have shorter timelines or greater expectations. Having already begun work on your water system inventory offers insurance against future requirements.

4. Faster Access to and Better Eligibility for Funding Sources

Once you understand the scale of your lead service line mitigation scope, you can make a more compelling funding request. Cities like Detroit and Toledo, which have used machine learning tools in their LSL inventory process early, have been able to access additional funding toward their LSL replacement programs.

Toledo is a great example of leveraging technology in an LSL solution. By embracing AI-guided predictive modeling while creating their lead service line inventory, they were able to unlock $10 million in funding to efficiently identify and replace lead service lines. This massively accelerated their lead service line removal program. What was initially estimated to be a 30 year LSL replacement program is now scheduled to take just five years.

Detroit similarly unlocked over $100 million in funding for lead service line removal, with more funding on the way.

5. It’s Later than You Think

Finally, and most importantly, the clock is, and has been ticking to complete your system’s service line inventory by October 2024. While that date may feel far away, it is just around the corner. And projects like these—ones with an unknown scope, relying on unreliable records—have a nasty habit of taking longer than anyone initially imagined. The time to build your LSL inventory is now!